Each Stiletto is built with a custom chin scoop that is designed to direct airflow towards the oil cooler. The scoop is accented with a custom hand-fabricated grill which not only looks good, but is extremely functional as well. We thought you might like to see some of the stages that go into fabricating such a relatively small piece. From concept to completion, each hand-crafted Stiletto component goes through the same process to ensure that every part, big or small, is constructed to the highest level of design and fabrication excellence. Please enjoy our process…

In this photo, you can see that the scoop is completely prepped. All painted areas are covered with blue tape to make sure no paint is scratched. Already installed is the wire mesh screen which serves two purposes. The most obvious is to protect the oil cooler from damage by any debris that may get kicked up while riding. The second purpose, being more aesthetic, is to provide a visual break between the actual grill and the oil cooler itself. It makes it more visually appealing. The screen is then rimmed with a stainless steel border which cleans up the edges and completes the look.

Each custom hand-fabricated component on the Stiletto begins as a cardboard template. These templates are carefully measured, cut out, fitted, and re-fitted if necessary.

The cardboard templates are then used to construct an actual three-dimensional model of the part that is to be fabricated. Before we even begin to touch metal, the model can be evaluated for fit, construction, and overall style and appearance. If we don’t like what we see, we start over until the results meet or exceed our expectations.

After we are satisfied with the template construction, we use those same templates to cut out the 20-gauge cold-rolled steel to size. Each piece then goes through another fitment process in which the steel is rolled, formed, and smoothed out in order to make the joints between the pieces as tight as possible. Taking the extra time to grind down the lips and edges helps to produce welds that are cleaner and more precise. This results in stronger welds that require less grinding and produce less warping in the steel.

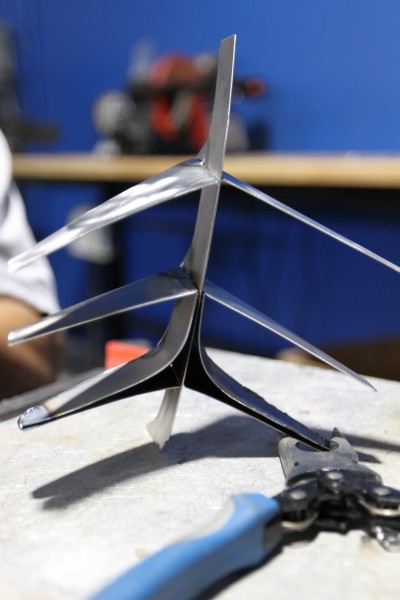

At this point, assembly can finally begin. All pieces are initially tack-welded together so the general shape of the part can be evaluated for correctness. Sometimes the welds need to be broken and pieces re-fabricated. In this case, the metal looked good and we could tack-weld all the pieces together.

After the initial welds are complete, a complete visual inspection takes place. The grill will also be test fitted into the scoop to check for any alignment or fabrication issues.

This photo shows us making some minor modifications to the ends of the grill fins. The alignment was off by only a little, so we were able to make some subtle bends and twists to bring the alignment into place. Also, because the grill is designed as a mirror image from side to side, both halves need to match up in terms of dimensions.

Once we are satisfied with the fit and alignment, we can complete our welds and fill in in-between the tacks. You can see in this photo that the top set of fins are being completed. Additional support is being welded in and the fins start to take on their three-dimensional look.

A final evaluation before moving on to the next step. Once the welds are complete, they will be ground down using an angle grinder. This process completely smoothes out the weld and make the component look like one solid piece. You can see the front of the grill in the next set of photos.

With the grill being fitted for the final time, you can see that the top set of fins are completed. Notice that the welds are completely ground smooth and have a beautiful one-piece look and finish. All that remains is to complete this process with the second and third fin sets. Taking the time to properly prep each piece is the key to making sure the outcome is correct. An extra ten minutes of grinding or bending in the beginning can lead to hours of time saved trying to fix mistakes at the end. All that remains is to complete the process with the rest of the grill and it will be finished.

Smooth and seamless is the end result. As you can see in this photo, the grill is complete and we even added a fourth fin set at the top of the grill. Adding the fourth fin at the top really completed the overall look and helped to tie the top and bottom of the scoop together. We’re very happy with the results and hope you are too.

Custom piece of art! One can only imagine, if so much time, attention and craftsmanship is taken on this component alone, can anyone fathom the amount of time taken on, say, the rear fender etc let alone the rest of this piece of art!